Common Pumping Liquids

Cov dej huv

Txhawm rau nqa tag nrho cov twj tso kua mis ntsuas nkhaus mus rau ib puag ncig, cov yam ntxwv ntawm lub twj tso kua mis yog raws li cov dej ntshiab ntawm qhov kub thiab txias (feem ntau 15 ℃) nrog qhov ceev ntawm 1000 kg / m³.

Cov khoom siv feem ntau ntawm kev tsim kho rau cov dej huv yog tag nrho cov cam khwb cia hlau los yog cam khwb cia hlau casing haum nrog bronze internals, Thaum siv cov dej huv, los yog dej zoo dua txhais tau tias nruab nrab nrog ib tug tshwj xeeb lub ntiajteb txawj nqus ntawm 1 uas tsis muaj cov khib nyiab tam sim no,kawg suction twjthiab kab rov tavcais cov twj tso kua misfeem ntau yog siv. Thaum xav tau lub taub hau siab, cov twj siv ntau theem tau siv.

Thaum cov neeg tsim qauv raug txwv rau qhov chaw twj tso kua mis hauv tsev, ntsug units ntawm ob qho tib si ntws, axial lossis turbine hom twj siv.

Hiav txwv dej raws li ib tug corrosive nruab nrab

Cov dej hiav txwv muaj tag nrho cov ntsiab lus ntsev txog li 25 g / ℓ. Txog 75% ntawm cov ntsev ntsev yog sodium chloride NaCl. pH-tus nqi ntawm cov dej hiav txwv feem ntau yog nyob nruab nrab ntawm 7,5 thiab 8,3. Hauv kev sib npaug nrog cov cua, cov ntsiab lus oxygen ntawm 15 ℃ yog li 8 mg / ℓ.

Degassed dej hiav txwv

Qee qhov xwm txheej, dej hiav txwv yog degassed chemical los yog physic-ally. Raws li qhov tshwm sim ntawm qhov no, aggressiveness poob considerably. Nyob rau hauv cov ntaub ntawv ntawm tshuaj degasification, nws yuav tsum tau muab sau tseg tias degassing yuav siv sij hawm. Yog li ntawd, nws yog ib qho tseem ceeb heev uas kev ua haujlwm degasification, piv txwv li tshem tawm cov pa oxygen, ua kom tiav ua ntej cov dej hiav txwv nkag mus rau hauv lub twj tso kua mis.

Kev saib xyuas yuav tsum tau ua hauv kev ua haujlwm - aeration yuav tshwm sim los ntawm huab cua inrush. Txawm hais tias cov inrushes tsis pub dhau lub sijhawm, kev puas tsuaj rau cov ntaub ntawv tuaj yeem tshwm sim sai heev nyob rau hauv qee qhov xwm txheej yog tias tsis pom cov pa oxygen thaum cov khoom raug xaiv. Yog tias cov pa oxygen tsis tuaj yeem raug cais tawm thaum lub twj tso kua mis ua haujlwm, feem ntau yuav tsum tau xav tias cov dej hiav txwv muaj cov pa oxygen.

Cov dej khov

Lo lus 'dej brackish' infers ib cov dej tshiab uas muaj paug nrog dej hiav txwv. Raws li kev xaiv cov khoom muaj kev txhawj xeeb, tib cov lus qhia siv rau kev thauj cov dej brackish xws li dej hiav txwv. Tsis tas li ntawd, dej brackish nquag muaj ammonia thiab / lossis hydrogen sulfide. Txawm tias muaj cov ntsiab lus qis ntawm hydrogen sulphide, piv txwv li hauv thaj tsam ntawm ob peb milligrams ib liter, ua rau muaj kev tawm tsam ntau ntxiv.

Dej hiav txwv los ntawm cov chaw hauv av

Cov dej ntsev los ntawm cov hauv av feem ntau muaj cov ntsev ntau dua li cov dej hiav txwv, feem ntau nws yog li 30%, piv txwv li nyob rau hauv cov kev txwv solubility. Ntawm no dua, cov ntsev ntau yog cov ntsiab lus tseem ceeb. Tus nqi pH feem ntau yog sib piv qis (txog li 4), piv txwv li cov dej yog acidulous. Txawm hais tias cov ntsiab lus ntawm cov pa oxygen tsawg heev lossis txawm tias tsis muaj, H₂S cov ntsiab lus yuav muaj li ntawm ob peb puas milligrams ib liter.

Xws li acidulous ntsev tov uas muaj H₂S yog corrosive heev thiab hu rau cov khoom tshwj xeeb.

Raws li qhov tshwm sim ntawm cov ntsiab lus ntsev siab thiab nyob ntawm qhov kev ua haujlwm, ib tus yuav tsum cia siab tias yuav muaj qee qhov dej los ntawm ntsev. Nyob rau hauv cov ntaub ntawv no, kev tiv thaiv tsim nyog yuav tsum tau ua raws li kev tsim, kev ua haujlwm thiab kev xaiv cov khoom siv.

Corrosion nyob rau hauv dej hiav txwv

Cov ntaub ntawv ua haujlwm tsis yog tsuas yog ua kom pom kev txaus siab rau kev hnav khaub ncaws zoo ib yam, tab sis kuj tiv thaiv kev xeb hauv zos tshwj xeeb pitting thiab crevice corrosion. Cov xwm txheej zoo li no tau ntsib tshwj xeeb tshaj yog nrog kev ua haujlwm ntawm tus kheej ferro alloys (stainless steels). Yog li-hu ua 'standby' twj, uas tsuas yog ua haujlwm tsis tu ncua, khiav txoj kev pheej hmoo ntawm kev ua haujlwm ruaj khov; Kev nyab xeeb nrog dej tshiab ua ntej lub sijhawm kaw lossis lub sijhawm pib ua haujlwm yog suav tias yog qhov zoo.

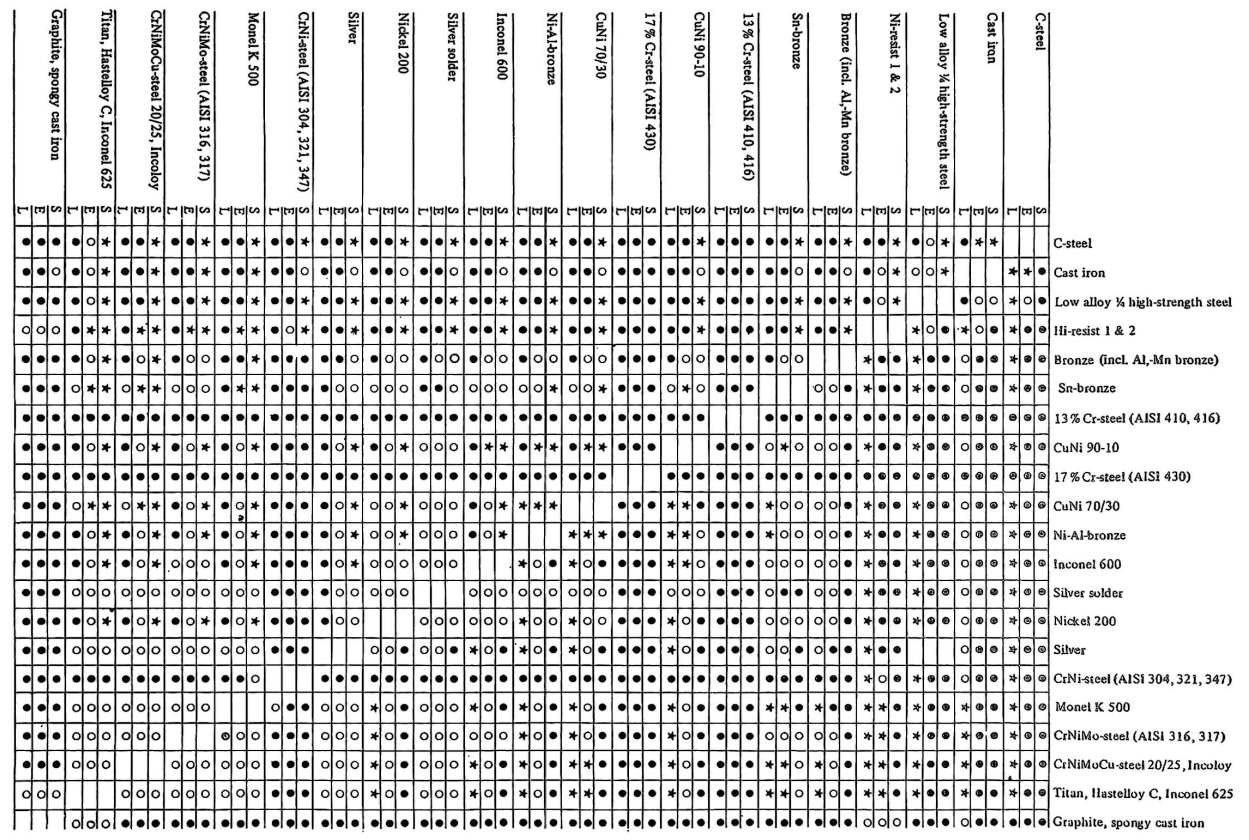

Qhov ntau yamdej hiav txwv twj tso kua misCheebtsam yuav tsum tau ua los ntawm cov ntaub ntawv ntawm tib hom nyob rau hauv thiaj li yuav tiv thaiv galvanic corrosion. Qhov muaj peev xwm sib txawv ntawm tus kheej cov ntaub ntawv yog kom tsawg li tsawg tau. Txawm li cas los xij, yog tias tsis zoo li cov ntaub ntawv yuav tsum tau ua haujlwm rau cov laj thawj tsim, qhov chaw ntawm cov hlau tsis tshua muaj siab nyob rau hauv kev sib cuag nrog dej yuav tsum loj nyob rau hauv kev sib piv nrog cov hlau noble. Daim duab 5 muab cov ntaub ntawv hais txog kev phom sij ntawm galvanic corrosion thaum cov khoom sib txawv sib xyaw ua ke.

Kev nrawm nrawm tuaj yeem ua rau corrosion corrosion. Cov kev tshwm sim dhau los ua qhov hnyav zuj zus, qhov hnyav dua qhov nruab nrab, thiab siab dua nws qhov nrawm. Whereas tus nqi ntws cuam tshuam rau tus cwj pwm ntawm stainless hlau thiab npib tsib xee alloys rau tsuas yog ib tug me me degree, txoj hauj lwm yog thim rov qab qhov twg unalloyed ferrous cov ntaub ntawv thiab tooj liab alloys koom nrog. Daim duab 6 muab cov ntaub ntawv zoo ntawm kev cuam tshuam ntawm cov nqi ntws. Kev txiav txim siab yuav tsum tau muab yog li ntawd seb qhov nruab nrab puas muaj oxygen lossis H₂S. Ntau qhov H₂S yuav tsis suav nrog cov pa oxygen; Nyob rau hauv xws li mob, qhov nruab nrab yog me ntsis acidulous, mus rau ib tug pH ntawm 4.

Kev coj cwj pwm

Table 1 ua cov lus pom zoo rau cov khoom siv twj tso kua mis lossis lawv cov kev sib xyaw ua ke. Tshwj tsis yog hais tias lwm yam, cov ntaub ntawv hauv qab no siv rau cov dej hiav txwv yam tsis muaj H₂S cov ntsiab lus.

Unalloyed steel thiab cam khwb cia hlau

Cov hlau tsis muaj hlau tsis haum rau cov dej hiav txwv, tshwj tsis yog tias nws tau muab cov txheej txheem tiv thaiv tsim nyog. Cam khwb cia hlau tsuas yog siv rau qhov qis tshaj tawm (ua tau rau cov casings); Nyob rau hauv cov ntaub ntawv no ib txwm cathodic tiv thaiv ntawm lwm yam internals yuav tsum tau ua hauj lwm.

Austenitic Ni-castings

Ni-Resist 1 thiab 2 tsuas yog haum rau nruab nrab tshaj tawm (txog li 20 m / s).

Galvanic Corrosion nyob rau hauv dej hiav txwv ntawm 5-30 ℃

Lub sij hawm xa tuaj: Mar-11-2025

sales@tkflow.com

sales@tkflow.com